Filter

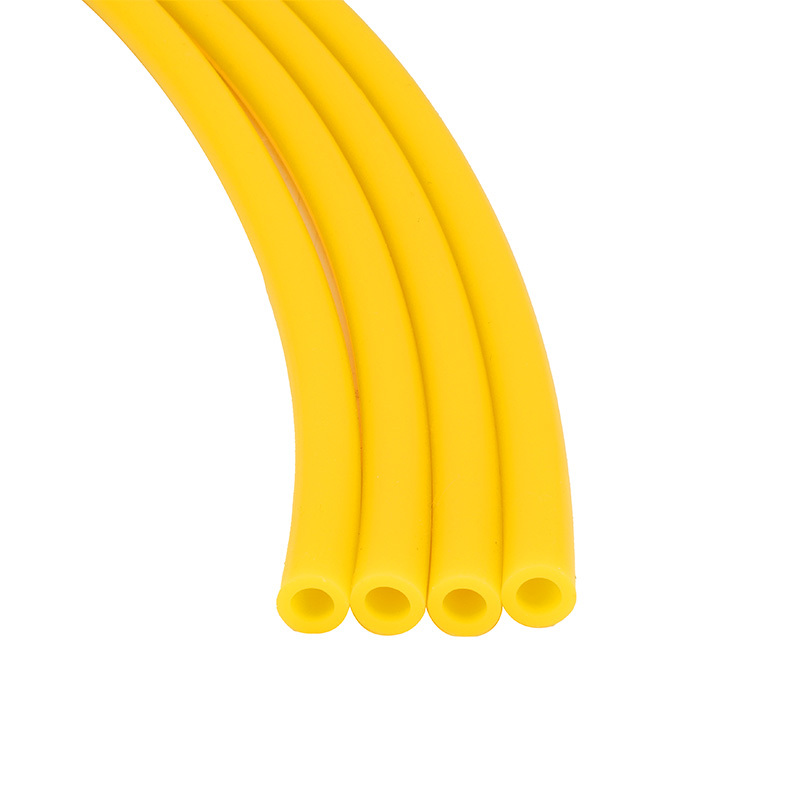

- Commodity name: Filter

- Product Description

-

Packing specification

According to various profiles matching strip, 25 Kg/box (bag)

Product Features

Completely solve the problem of ventilation at the hinge, easy to operate, the best sealing.

Scope of application

Curtain wall, sealed doors and windows.

Silicone sealing strip for doors and windows is an important building material, which plays a key role in the installation of doors and windows. This kind of sealing strip has excellent characteristics, not only can effectively prevent the penetration of water, gas and noise, but also can provide good heat preservation and sound insulation effect.

Rubber strip technical indicators:

The standard "Sealing Strip for Building Doors and Windows" (JG/T187-2006) has been released and published and has been officially implemented since June 1, 2007. In order to facilitate door and window manufacturers, real estate users, developers, etc. to understand the standard requirements of door and window sealing strips, and correctly select qualified products to ensure the sealing performance of doors and windows to ensure the realization of the overall energy-saving requirements of buildings, the main performance indicators of materials and products in the standard of "Sealing Strip for Building Doors and Windows" are introduced:Requirements

The appearance should be smooth, no distortion, no cracks, no bubbles, no obvious impurities and other defects on the surface, uniform color.

Dimensional tolerance: The sectional dimensional tolerance of the sealing strip shall be in accordance with Table 2 in GB/T3672.1-2000. The assembly dimension shall be in accordance with Grade E1, and the non-assembly dimension shall be in accordance with Grade E2. The geometric tolerance of the sealing strip shall be in accordance with Grade N in GB/T3672.1-2000.

Performance

Physical properties of materials: the physical properties of materials used for vulcanized rubber sealant strips shall comply with the provisions of (Table 1), and the physical properties of materials used for thermoplastic elastomer sealant strips shall comply with the provisions of (Table 2).

Note: Commonly used thermoplastic elastomer strips: thermoplastic vulcanizate (TPV), polyurethane thermoplastic elastomer (TPU), plasticized polyethylene (Prvc) strips, etc.

Performance of sealant strip products

rebound recovery

Classification of rebound recovery (Dr) of sealant strip products:

Level 1: 30% level 2: 40% level 3: 5lr <= 60% level 4: 60% level 5: 70% level 6: 80% level 7: 90%

Heating shrinkage rate: the length shrinkage rate of sealant strip products should be less than 2%

After the contamination and compatibility test, it is allowed to leave the contamination contour of the rubber strip sample light yellow on the profile and glass, and no dark contour or solid contour is allowed.

Key words:

Product inquiry

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!

Related Products