Exploring the Chemical Resistance of EPDM Rubber Sealing Strips: A Comprehensive Guide

Exploring the Chemical Resistance of EPDM Rubber Sealing Strips Table of Contents 1. Introduction to EPDM Rubber 2. Key Properties of EPDM Rubber Sealing Strips 3. Chemical Resistance of EPDM Rubber 4. Applications of EPDM Rubber Sealing Strips 5. Benefits of Using EPDM Rubber Sealing Strips 6. Factors Affecting Chemical Resistance 7. Maintenance and Care for EPDM Seal

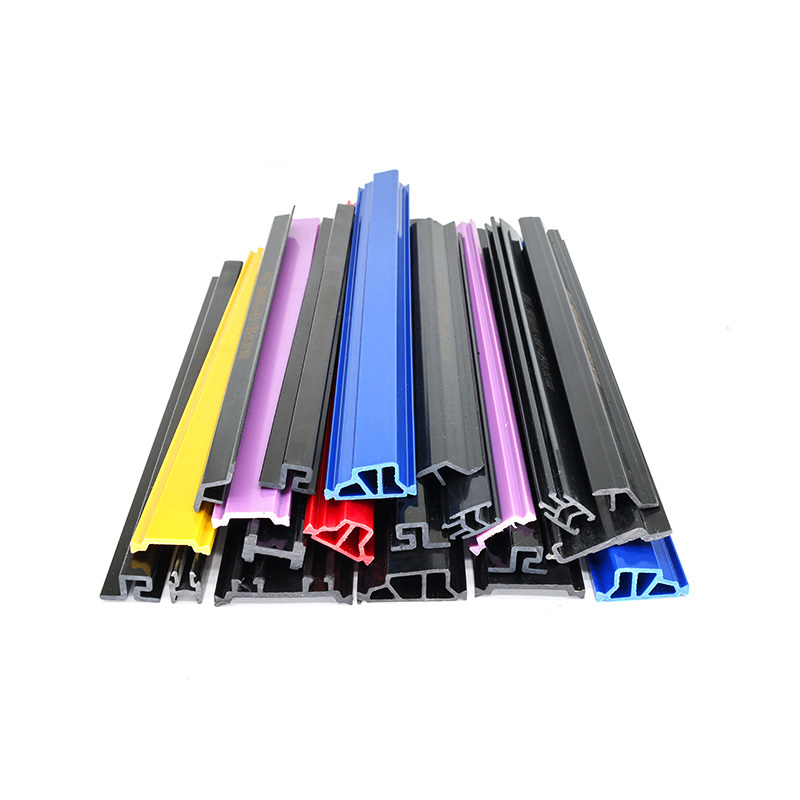

Exploring the Chemical Resistance of EPDM Rubber Sealing Strips

Table of Contents

- 1. Introduction to EPDM Rubber

- 2. Key Properties of EPDM Rubber Sealing Strips

- 3. Chemical Resistance of EPDM Rubber

- 4. Applications of EPDM Rubber Sealing Strips

- 5. Benefits of Using EPDM Rubber Sealing Strips

- 6. Factors Affecting Chemical Resistance

- 7. Maintenance and Care for EPDM Sealing Strips

- 8. Conclusion

- 9. FAQs

1. Introduction to EPDM Rubber

Ethylene Propylene Diene Monomer (EPDM) rubber is a versatile synthetic elastomer known for its exceptional performance in various environmental conditions. This durable material is widely used in sealing strips due to its outstanding flexibility, resistance to UV radiation, and ability to withstand extreme temperatures. Understanding the fundamental characteristics of EPDM rubber helps in appreciating its role in sealing applications across multiple industries.

2. Key Properties of EPDM Rubber Sealing Strips

EPDM rubber sealing strips possess several key properties that make them a preferred choice in sealing applications. Here are some of the most notable:

2.1 Excellent Weather Resistance

EPDM rubber exhibits exceptional resistance to ozone, UV rays, and extreme weather conditions. This makes it ideal for outdoor applications where exposure to the elements is a concern.

2.2 High Temperature Tolerance

EPDM rubber can withstand temperatures ranging from -40°F to 250°F (-40°C to 121°C), maintaining its performance in both cold and hot environments.

2.3 Low Compression Set

The low compression set of EPDM rubber means it retains its shape and sealing properties over time, even under pressure, ensuring a long-lasting seal.

2.4 Good Electrical Insulation Properties

EPDM rubber is an excellent electrical insulator, making it suitable for applications in the electrical and automotive industries.

2.5 Chemical Resistance

One of the standout features of EPDM rubber is its remarkable resistance to various chemicals, which we will explore in detail in the subsequent sections.

3. Chemical Resistance of EPDM Rubber

EPDM rubber sealing strips are known for their impressive chemical resistance, allowing them to be used in a variety of industrial environments. Let’s explore this aspect in detail:

3.1 Resistance to Acids and Bases

EPDM rubber shows good resistance to both weak acids and bases, making it suitable for applications in chemical processing and manufacturing. However, it is essential to test compatibility with specific chemicals before use.

3.2 Resistance to Hydrocarbons

While EPDM can resist some hydrocarbons, it is not suitable for prolonged exposure to oils and solvents. Understanding the specific chemical environment is crucial when selecting sealing materials.

3.3 Resistance to Water and Steam

EPDM rubber has excellent resistance to water and steam, allowing it to maintain its sealing properties in wet environments. This characteristic makes it a popular choice for plumbing and HVAC applications.

3.4 Thermal Aging Resistance

EPDM rubber maintains its properties under thermal aging, ensuring long-lasting durability in high-temperature environments.

4. Applications of EPDM Rubber Sealing Strips

The versatility of EPDM rubber sealing strips lends itself to a variety of applications across multiple industries. Here are some notable examples:

4.1 Automotive Industry

EPDM sealing strips are extensively used in vehicles for weather stripping, door seals, and window seals, providing effective noise reduction and insulation.

4.2 Construction Industry

In construction, EPDM rubber is utilized for roofing systems, window frames, and facades due to its weather resistance and durability.

4.3 Electrical and Electronics

The excellent electrical insulation properties of EPDM make it suitable for use in electrical connectors and seals.

4.4 HVAC Systems

EPDM sealing strips are commonly found in HVAC systems, providing effective seals that enhance energy efficiency and performance.

4.5 Industrial Equipment

In industrial machinery, EPDM seals are essential for preventing leaks and ensuring operational efficiency in various processes.

5. Benefits of Using EPDM Rubber Sealing Strips

Utilizing EPDM rubber sealing strips offers numerous advantages:

5.1 Cost-Effectiveness

EPDM rubber is relatively low-cost compared to other sealing materials, making it a cost-effective solution for manufacturers and consumers alike.

5.2 Versatility

The adaptability of EPDM rubber allows it to be used in various applications, providing flexibility for manufacturers.

5.3 Performance Longevity

Thanks to its low compression set and resistance to environmental factors, EPDM sealing strips offer a longer lifespan, reducing the need for frequent replacements.

5.4 Environmental Resistance

EPDM rubber is capable of withstanding harsh conditions, making it suitable for both indoor and outdoor applications without degradation.

6. Factors Affecting Chemical Resistance

Understanding the factors that influence the chemical resistance of EPDM rubber is crucial for ensuring optimal performance:

6.1 Concentration of Chemicals

The concentration of the chemical exposure can significantly impact the longevity and effectiveness of EPDM sealing strips.

6.2 Temperature of Exposure

Higher temperatures can accelerate chemical reactions and degradation, affecting the performance of EPDM rubber.

6.3 Duration of Exposure

Prolonged exposure to certain chemicals can lead to deterioration. It is essential to evaluate the environment to ensure compatibility.

6.4 Presence of Additives

Additives in formulations can alter the chemical resistance of EPDM rubber. Knowing the composition of the surrounding environment is key.

7. Maintenance and Care for EPDM Sealing Strips

To maximize the lifespan and performance of EPDM rubber sealing strips, proper maintenance is essential:

7.1 Regular Inspection

Conduct regular inspections to identify signs of wear, cracking, or environmental damage that could compromise the seal.

7.2 Cleaning Procedures

Use mild, non-abrasive cleaning agents to remove dirt and debris without damaging the rubber.

7.3 Replacement Considerations

Be prepared to replace sealing strips that show significant wear or damage to maintain effective sealing performance.

8. Conclusion

EPDM rubber sealing strips are a powerful solution for a variety of sealing needs, thanks to their impressive chemical resistance and adaptability. Their unique properties make them an excellent choice in industries ranging from automotive to construction. Understanding the factors affecting their performance and taking proactive measures for maintenance can significantly extend their lifespan and effectiveness.

9. FAQs

What is EPDM rubber?

EPDM rubber is a synthetic elastomer known for its excellent weather resistance and durability, making it ideal for various sealing applications.

How does EPDM rubber perform against chemicals?

EPDM rubber offers good resistance to weak acids, bases, and water, but may not withstand exposure to oils and solvents.

Can EPDM sealing strips be used outdoors?

Yes, EPDM sealing strips are highly resistant to UV rays and weather conditions, making them suitable for outdoor applications.

What is the temperature range for EPDM rubber?

EPDM rubber can perform effectively in temperatures ranging from -40°F to 250°F (-40°C to 121°C).

How do I maintain EPDM rubber sealing strips?

Regular inspections, mild cleaning, and timely replacements are essential for maintaining the performance of EPDM sealing strips.

This detailed exploration of EPDM rubber sealing strips provides a comprehensive understanding of their chemical resistance and applications. By leveraging this knowledge, industry professionals can make informed decisions regarding sealing solutions that meet their specific needs.

Previous: